Aluminum profile manufacturing: How are aluminum profiles made?

Aluminum is a lightweight, strong and versatile metal that is widely used in various industries. One popular form of aluminum is aluminum profiles, which are used in construction, automotive, furniture and many other fields. In this article, we will take a closer look at the production process of aluminum profiles in Poland, discussing the stages of their manufacture, the types of technologies used and trends in this field.

Raw materials and preparation

The basic raw material for the production of aluminum profiles is aluminum alloy. The most commonly used alloys are the 6000 series, which are characterized by good strength and corrosion resistance. The aluminum alloy is melted in a furnace and poured into special molds, where it forms ingots. These ingots are then heat-treated to obtain the right structure and properties.

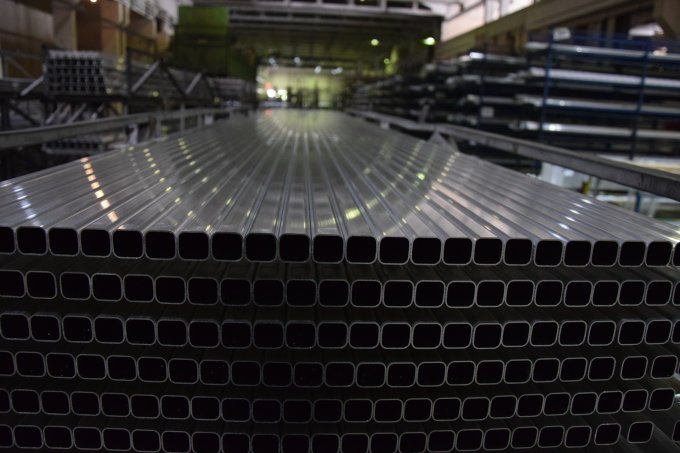

Extrusion of profiles

The main stage in the production of aluminum profiles is extrusion. In this process, the aluminum alloy, heated to about 500°C, is pressed through a die shaped to match the desired profile geometry. These dies are made of tool steel and can be of various shapes, allowing the creation of profiles with a variety of cross-sections, such as rectangular, circular, oval, trapezoidal and others.

Cooling and straightening

After extrusion, the aluminum profiles are quickly cooled to fix their shape. They are then straightened to remove any deformation created during the extrusion process.

Finishing

Aluminum profiles can be subjected to various finishing processes to give them the right properties and aesthetics. The most popular finishing processes include:

- Anodizing: Anodizing is an electrochemical process that forms an oxide layer on the aluminum surface. This layer protects the profile from corrosion and gives it an aesthetic appearance.

- Varnishing: Aluminum profiles can be powder-coated or wet-varnished. Varnishing protects the profile from corrosion and gives it any color.

- Sanding: Sanding gives aluminum profiles a smooth and satin-like surface.

Cutting and machining

Aluminum profiles can be cut to any length and subjected to various machining processes such as drilling, milling, threading and bending. This allows profiles to be customized to meet individual customer needs.

Application of aluminum profiles

Aluminum profiles are widely used in various fields, including:

- Construction: aluminum profiles are used to build windows, doors, facades, roof structures, fences and many other components.

- Automotive: Aluminum profiles are used to build vehicle frames, bodies, interior components and other components.

- Furniture: Aluminum profiles are used to make office, kitchen, garden and other furniture.

- Other applications: Aluminum profiles are also used in engineering, electronics, aerospace and many other industries.

Check out a reputable aluminum profile manufacturer at https://extral.com/en

Trends in the production of aluminum profiles

In recent years, there have been several trends in the production of aluminum profiles:

Increasing the share of high-strength aluminum alloys: These alloys are increasingly used in structures where high strength and lightness are required.

Development of extrusion technology: New extrusion technologies allow the creation of profiles with increasingly complex shapes and better properties.

Increasing importance of ecology: Manufacturers of aluminum profiles are paying more and more attention to environmental protection. They are introducing new technologies to reduce energy consumption and emissions.

Summary

Aluminum profiles are a versatile and forward-looking construction material that is widely used in various fields. As technology develops and environmental awareness increases, aluminum profiles will continue to play an increasingly important role in many industries.

See more

Jakie są możliwości franczyzowe?

Restructuring - effective aid for many companies